Analysis of the market space of brake-by-wire systems: electrification and intelligence promote market development

The brake-by-wire system is the electronic control brake system, which is divided into a mechanical brake-by-wire system and a hydraulic brake-by-wire system.

mechanical

Mechanical brake-by-wire system (abbreviated as EMB) EMB is completely different from conventional hydraulic braking systems. EMB uses electric energy as an energy source, drives the brake pads through a motor, and transmits energy by wires, and data wires transmits signals. EMB is a wire system. A kind of dynamic system. There is no brake pipeline connected in the whole system, the structure is simple, the volume is small, the signal is transmitted through electricity, the response is sensitive, the braking distance is reduced, the work is stable, the maintenance is simple, there is no hydraulic oil pipeline, there is no hydraulic oil leakage problem, through ECU Direct control, easy to realize ABS, TCS, ESP, ACC and other functions.

Hydraulic

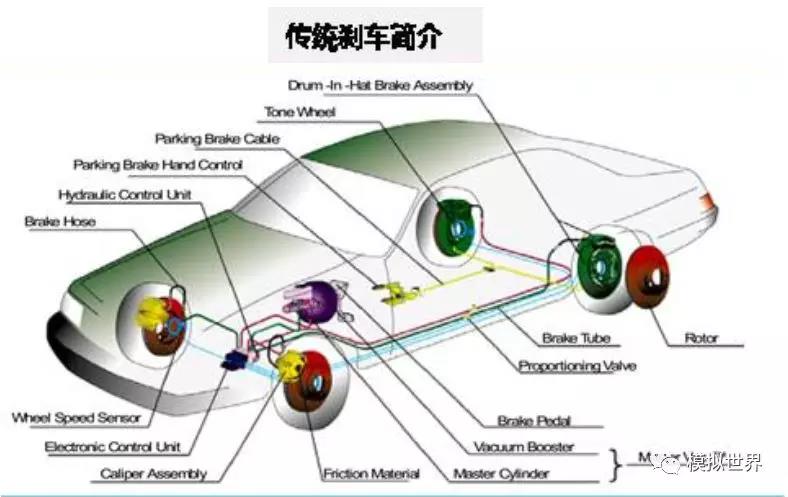

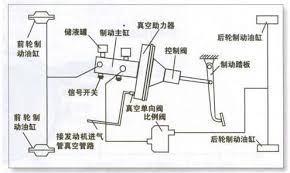

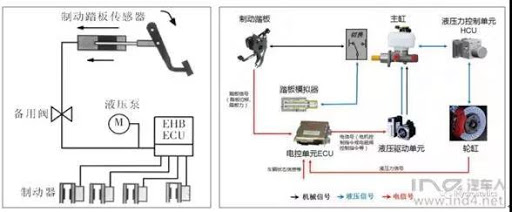

Hydraulic brake system (Electronic Hydraulic Brake System, EHB) EHB is developed from the traditional hydraulic brake system, but it is very different from the traditional brake method. EHB replaces the original part with electronic components Mechanical components are an advanced mechatronics system that combines electronic systems and hydraulic systems. EHB is mainly composed of electronic pedal, electronic control unit (ECU), and hydraulic actuator. The electronic pedal is composed of a brake pedal and a pedal sensor (pedal displacement sensor). The pedal sensor is used to detect the pedal stroke, and then convert the displacement signal into an electric signal and send it to the ECU electronic control unit to realize the proportional regulation of the pedal stroke and braking force.

Electricity and intelligence promote the development of wire control. For traditional fuel vehicles, the engine is generally used to provide vacuum assistance; while electric vehicles do not have an engine to provide vacuum assistance, an electronic vacuum pump or a brake-by-wire system is required. For smart cars, especially L3 and above self-driving cars, the response time of the braking system is particularly important, and the brake-by-wire response is faster, which is an important guarantee for the safety of automatic driving.

The brake-by-wire system is developed from the traditional braking system. The use of electric systems to replace traditional mechanical or hydraulic systems is the long-term development trend of automobile braking technology. The traditional braking system applies energy from the brake pedal and transmits it to the brake via hydraulic or pneumatic pipelines; while the execution information of the brake-by-wire system is transmitted by electrical signals, and the braking pressure response is faster, so the braking distance is shorter and safer.

The brake-by-wire system is also divided into two types: EHB/EMB.

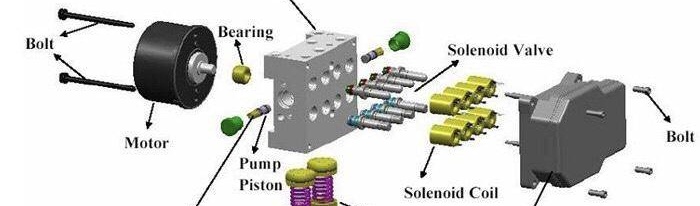

1) The hydraulic brake-by-wire EHB (Electro Hydraulic Brake) is based on the traditional hydraulic brake system, replacing part of the mechanical parts with electronic devices, using brake fluid as the power transmission medium, and the control unit and actuator arrangement It is relatively centralized, with a hydraulic backup system, which can also be called a centralized or wet braking system.

2) Mechanical brake-by-wire EMB (Electro Mechanical Brake) uses electronic mechanical devices instead of hydraulic lines. The actuator is usually installed on the side of the wheel. It can also be called a distributed, dry brake system.

On the whole, the EHB system has a higher level of safety due to its backup brake system, and therefore has a higher acceptance. It is currently the main solution to promote mass production. Although the EMB system has many advantages, it lacks a backup brake system and lacks technical support. It is difficult to apply in large quantities in the short term, which is the direction of future development.

The line control in the L2 era can be divided into three categories: fuel vehicles, hybrid vehicles, and pure electric vehicles. Most fuel vehicles use ESP (ESC), and hybrid vehicles basically use indirect EHB (Electro-Hydraulic Brake) with a high-pressure accumulator as the core. ), pure electric vehicles basically use direct EHB, which directly pushes the piston of the master cylinder with a motor.

The current unit price of the wire control system is about 2,500 yuan. In the future, as the production and sales increase will bring cost reduction, the price is expected to drop to about 2,000 yuan. Based on the domestic passenger car sales of 23 million and 27 million in 2020 and 2025, respectively, and the penetration rate of the line control system is 10% and 30%, respectively, the market space of the domestic line control system in 2020 and 2025 are respectively estimated. It is 5.8 billion yuan and 16.2 billion yuan.

From the perspective of the development stage, the brake-by-wire is still in the early stage of development. The current penetration rate is low, and only a few models are equipped, and the new energy vehicle configuration rate is relatively high. With the gradual penetration of new energy vehicles, L3 and above intelligent driving, wire-by-wire control is expected to explode. According to the above forecast, the average annual compound growth rate of the market space of the line control from 2020 to 2025 is as high as 23%.

EHB foreign manufacturers are already relatively mature in technology development, and the country is trying to catch up; EMB is still in the research stage, and it is difficult to make breakthroughs in the short term. At present, the main suppliers of brake-by-wire systems include Bosch, ZF, Continental and other international component giants. Most of them have begun research and development since the end of the 1990s. They have rich technology accumulation and supply experience in the field of chassis control, and have certain First mover advantage.

Beginning in 2000, some domestic independent vehicle companies and component suppliers have begun to conduct EHB research and development, and have achieved certain results. Although there is still a certain gap with international giants such as Bosch, the industry is still in the early stage of development and there is still a greater chance of catching up.

From the perspective of competition factors, the technological content of the line control products is relatively high, and requires a long investment period, so the requirements for talents, technology and capital are relatively high. At present, Bethel, Tuopu Group, Wanan Technology, etc., which have relatively good development in China, have the advantages of talents, technology and capital, and are expected to gain a place in the future market competition.

Bethel: The company released WCBS products in July 2019, providing customers with a one-box integrated solution, which not only integrates the functions of vacuum booster, electronic vacuum pump, master cylinder and ESC, but also better meets the needs of new energy vehicles As well as the new requirements for the braking system of the intelligent driving of the whole vehicle.

Tuopu Group: The company has been committed to the development of automotive electronic products for many years. It has successively developed EVP and other products and achieved mass production. In the field of online control, the intelligent brake system IBS product developed by the company is still in the verification and market pre-promotion stage. It is expected to be To achieve mass production in 2021-2022.

Wanan Technology: The EHB products of the shareholding company Shanghai Tongyu Automobile Technology Co., Ltd. have cooperated with many customers such as Jiangling Group and Cainiao Logistics. At present, nearly 500 vehicles have been installed, involving passenger cars, light buses and other models. The product maturity is high, reaching the domestic leading level, and it is planned to achieve mass production in 2019.