The use and function of medium density fiberboard

Medium-density fiberboard is a kind of man-made board made of wood or plant fiber through mechanical separation and chemical treatment methods, mixed with adhesives and waterproofing agents, etc., and then formed by high temperature and high pressure. It is an ideal man-made board for making furniture. The structure of MDF is more uniform than that of natural wood, and it also avoids problems such as decay and insects. At the same time, it has small expansion and contraction and is easy to process. Because the surface of the medium density fiberboard is flat, it is easy to paste various finishes, which can make the finished furniture more beautiful. In terms of bending strength and impact strength, it is better than particleboard.

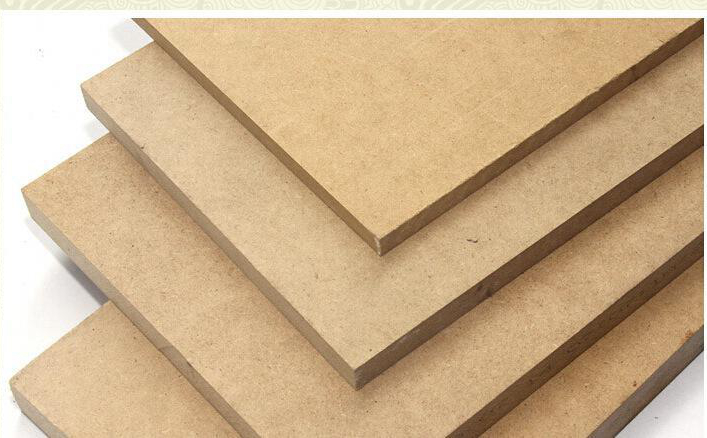

Medium-density fiberboard is made of small-diameter logs, cutting, processing residues, and non-woody plant fiber raw materials, after slicing, cooking, fiber separation, drying, applying urea-formaldehyde resin or other suitable adhesives, and then hot pressing. Kind of man-made panels. The density is generally in the range of 500-880 kg/m3, and the thickness is generally 2-30 mm.

Medium-density fiberboard is a product developed in the mid-sixties, and then developed rapidly. The reason is that it has excellent physical and mechanical properties, decorative properties and processing properties.

Mechanical properties

Because the fiber structure of the board is uniform and the bonding strength between the fibers is high, its static bending strength, planar tensile strength, and elastic modulus are better than particle board. The screw holding force, moisture absorption, water absorption performance, and thickness expansion rate are low.

Decoration performance

Because the surface of the medium density fiberboard is flat and smooth, it is convenient for gluing veneer and tissue paper and other facing materials, and it is convenient for finishing and saving paint.

Processing performance

Medium-density fiberboard can be produced from a few millimeters to tens of millimeters thick plates, which can replace any thickness of wood and square wood, and has good mechanical processing performance, such as sawing, drilling, grooving, tenoning, sanding and engraving , The edge of the board can be processed in any shape, and the surface is smooth after processing.

Because of its excellent performance and an effective way for comprehensive and reasonable utilization of wood, MDF is one of the most promising products at present.

Furniture industry: all kinds of panel furniture, table furniture, used in the production of various furniture components, such as panels, side panels, back panels, office screens, etc.

Construction and decoration industry: Typical applications include: laminate flooring (normal or moisture-proof MDF), wall panels, ceilings, doors, door skins and door openings, various indoor partitions, and building accessories such as: stairs, skirting, Mirror frame, various decorative panels and decorative lines. Vehicle and ship manufacturing: After being veneered, MDF can be used for interior decoration of ships, trains, and automobiles. It can replace plywood. However, when the environment is humid and the fire protection requirements are high, it can be laminated or special type of MDF solve.

Audio equipment: Medium-density fiberboard is a homogeneous and multi-porous material with good acoustic performance. It is very suitable for speakers, TV casings, and musical instruments.

Other applications: MDF can also be used in many places, such as: luggage frames, packaging boxes, ceiling fan blades, heels, toy puzzle blocks, clock shells, billboards-outdoor signs, display stands, shallow trays, ping-pong tables , Sculptures, models, etc.

6. Special medium-density fiberboard: The moisture-proof medium-density fiberboard is currently used for heel materials and floor boards, with thickness specifications of 4.75 mm, 6 mm, and 8 mm respectively. The significance of using a moisture-proof board for the heel material is that the heel must first be moisture-proof, and at the same time have good physical and mechanical properties, which can prevent cracking and wear. The significance of using a moisture-proof board for the floor is that the board must have a moisture-proof function to prevent bending deformation and thickness expansion caused by moisture absorption, and at the same time, it has good physical and mechanical properties and improves the quality of the product.

Medium density fiberboard

Hardboard

medium-density fibreboard

mdf板

MDF

Particle board

MDF Board

Chipboard

所有评论仅代表网友意见